|

|

|

|||||||

| Mini Buggy General Discussion General Discussion forum for Mini Buggies. (American Sportworks, HammerHead, Carter, etc) |

|

|

Thread Tools |

|

#1

|

|||

|

|||

|

I'm having a hell of a time getting my brakes back to normal. This weekend I installed a new master from BD. and that said did the recommended bleeding by BD site. Have a brake pump bleeder. And tried to bleed the brakes the old way by pumping. I have no brakes. And seems like no matter how much I pump, I can't get the air out of the lines. Even after using the gravity method. After filling it. Still have no brakes. Do I have a leak? Seals not good? Caliper not good? I've been messing with this for many weeks now. I'm getting over frustrated!!!

Note: I did weld a mount for my speedo on the caliper bracket. Could the caliper got hot and seals bad? Any help I would love to hear. Is there a way to test for leaks or bad seals? Thx. And yes. Have plenty of pad left. |

|

#2

|

|||

|

|||

|

Little more info: drakes do engage. Just not good. Use to be able to lock them up I wanted. No where close now. And changed out the brake line with a different one. (Not new). But looked in better condition. Might been wrong. Not safe to run with little brakes I do have.

Thx. |

|

#3

|

||||

|

||||

|

hey tk call Tom at this # , he can surely tell you how to do it and if you need any parts he will be able to help with that also. Contact Tom today

Phone (662)-301-1563 |

|

#4

|

||||

|

||||

|

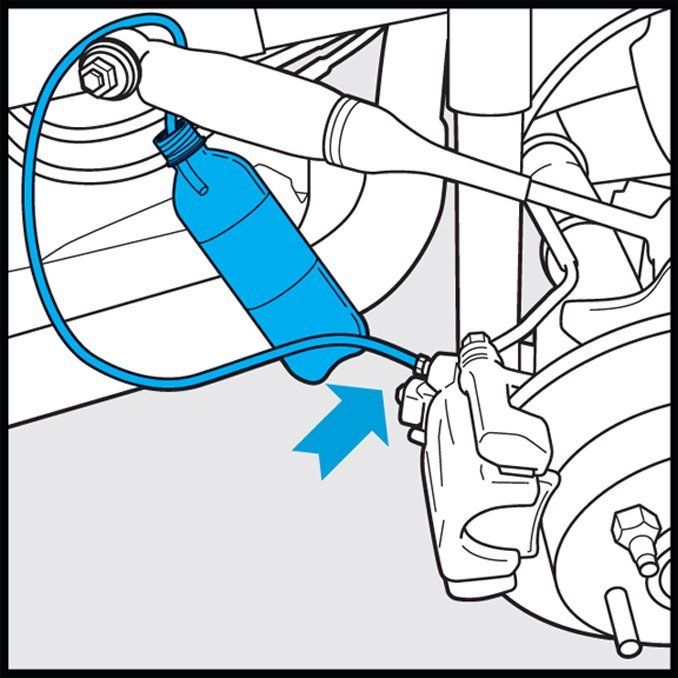

have you tried pushing fluid from the caliper up through the system? a $1.50 livestock syringe does a great job. these little masters can be a bugger to get all the air out of. With a hand pump style, sucking from the caliper you'll pull air in around the bleeder screw threads all day long--it'll drive you crazy.

|

|

#5

|

|||

|

|||

|

K man. I work road construction. So long hrs now. But do have some slow morning half the time. So will give him a call. Why frustrated. Very limited time to work on it now. And to much spare time been working on same thing.

Ya Xb seems like that is what happening. Pulling air through the bleeder. Even changed out bleed with what looked like a better one. And put TEF tape on threads. Don't think helped. Will try what u suggested. But never heard or seen what you said. Livestock syringe???? Not sure what that is. Or where I can get one. Could u give a few more details. Plz. And the price is right.  Thx guys |

|

#6

|

||||

|

||||

|

Livestock syringe is just a bigger version of the plastic syringe like they give with kid's medicine these days. tractor supply, local feed and grain stores etc.

Been there and done that with all the bleeder attempts you mention. the small size of the lines and orifices in the master, makes the suction pull air around the threads rather than fluid through the lines because the air can move thru more easily than the fluid can thru the lines. pumping fluid in reverse through the system is the way to go. syringe and a clear piece of hose. empty the reservoir and watch it as it fills while your pumping the fluid in at the caliper. just have to be careful when filling the syringe that you draw any air out of the hose, up into the syringe, then have it pointing straight down so that you don't pump it back into the system. |

|

#7

|

|||

|

|||

|

OK. Thx xbird. Will give it a shot. Can't hurt anything, that's for sure. And makes since. I almost got the calipers switched out with a spare one I had. Just in case. Wasn't til was time to drain the system that I was out of fluid. I saved most of fluid that has been going in and out of it. But fluid was dirty. Figured why put the dirty stuff in when cost $3.00 to ensure clean.

I'm assuming for this to work. The reservior needs to be higher that the master. Sounds promising. Thx again. Just need to find time to run across town while they are still open.  . .

|

|

#8

|

|||

|

|||

|

I like to use a clear hose on the bleeder so I can see whats going on.

Looping the hose over something higher than the caliper allows air to rise and fluid to fall. This way you can keep the bleeder open and just pump away without worrying about getting air in the system. Make sure the bleeder is at the top of the caliper, I have seen people install different calipers and the orientation of the bleeder is wrong. Doing it this way allows you to push air out of the system easier than the old ''pump pump open'' method. Keeps the air bubbles moving out rather than letting them float back upstream when you stop to ''pump pump open'' P.S Teflon tape on the threads of the bleeder can be counter productive, the bleeder seals at the bottom cone shaped area not the threads. Last edited by liduno; 04-07-2015 at 09:13 AM. |

|

#9

|

|||

|

|||

|

Ya. I made sure the TEF tape stayed on the threads only. And I'm pretty sure by now, as many times I've opened and closed the bleeder. Its not doing much good.

What amazed me was how dirty the fluid was my just try to bleed it through. Brand new clear fluid completely through system. But the container catching the fluid was almost black after pushing through. |

|

#10

|

|||

|

|||

|

It wasn't doing any good in the first place. The threads are not where the bleeder seals, it seals by jamming the cone shaped bottom of the bleeder into the cup shaped pocket in the caliper.

|

|

#11

|

||||

|

||||

|

the teflon tape was an attempt to stop sucking air in during the bleeding process ... don't ask me how i know ... .))))

|

|

#12

|

|||

|

|||

|

Oh Ok that makes sense if you're sucking through the bleeder.

|

|

#13

|

|||

|

|||

|

LOL. thats right X-bird. Did not help any putting the TEF tape on. was a suggestion on the instruction on the hand pump.

Well a slight update. I got the syringe. And did as you suggsted. When I got to the point where the fluid was all the way up in the Res. I reached for my wrench to tighten up the bleeder. Realized I didn't have it in a close reach. Was a long grab. When I grabbed it, the hose came off the syringe, and shot fluid everywhere!!!  by time I got the bleed shut off, pretty sure, air was sucked back in.  Only had time to try it once and then had other things to do. However, I did try pumping the breaks, and It did seem to have more pressure than I've had in a while. Did a quick test, and still not good enough. sure air got sucked back in. So hopfully will have time again today to try. |

|

#14

|

||||

|

||||

|

as long as it didn't drain the reservoir down into the hose, you'll be fine. that's the beauty of doing it reverse--if the hose pops off it will jut push fluid back out, no air can get in, I modded a mity vac fitting and remove the bleeder entirely when i do mine.

I make sure that i push a lot of fluid through the system (about 2-3 reservoir loads) to be certain i get everything trapped in or around the master and where lines make up/down bends if any. |

|

#15

|

|||

|

|||

|

I worked on it yesterday. I tried using a different caliper. That didn't work. But at that time I noticed that the brake linkage was hitting the frame when pushing the petal so far down. And did not appear that was pressing all the way on the master cylinder. Which might explain when I did have pressure, but brakes not engaging all the way. I thought maybe I had that linkage bar backwards. But after looking at a few pics. Seems I had it correct. The long section connects to the brake pedal. Is this normal? For linkage bar to hit the frame? Maybe to stop from pushing to far into the master? Is the linkage warn down to wear I need to adjust it, or even do a little grinding on bar/bracket so don't hit the frame? Anyone else have same issue?

|

|

#16

|

|||

|

|||

|

One other thing. When pushing fluid in caliper with syringe, the fluid is also pushing out of the threads. Just a little. But noticeable. Is this normal x-bird? Or do I need to look at replacing the bleeder?

|

|

#17

|

||||

|

||||

|

normal, and nothing to worry about at all.

Once you have solid fluid in the filler line from bleeder up into the syringe, it can only force air out from around the threads since the threads are before the opening in the other end of the bleeder. Any air in those thread gaps is going to come outwards and backwards, and not get drawn in. When you remove the filler line with the reservoir open, fluid comes out the bleeder from gravity, again it's keeping air out. It's easier for air to move around those threads while using a mity vac, so that sort of shows why that deal is not worth the effort. that leakage is good when pushing, bad when pulling since you never know if it's thread leakage air or air from in the brake system. I pumped air from my system with a mity vac over and over for days and days thinking i must be going nuts or had a cracked hose, fitting, master, banjo bolts, washers ... wasted several weeks on brakes thinking there was a problem. it was just the wrong tool and approach. Got a picture of brake linkage and master setup? Last edited by x-bird; 04-10-2015 at 12:46 AM. |

|

#18

|

|||

|

|||

|

Ya. I can get some pics. Worked on it last night. Something is up. I've got to have something in the line that shouldn't be there. I think. I was pushing fluid through. Then all of a sudden it stopped. No matter how much I pushed. Something was blocking it somewhere in the system. Is it possible to have the line connections to tight? Anyway, after that got frustrated and stopped for the day. Only thing I can think of now is to pull it outside and try somehow to clean the system. Only thing I can think of is blowing it out with air compressor. By the way it acted. Seems like might be around the master. Thinking of taking the piston out of master cylinder and blow air in from the brake line connection from the caliper. Good - bad. Idea?

|

|

#19

|

|||

|

|||

|

If you can't push fluid through, make sure the peddle or linkage isn't putting any pressure on the master. If there's even a little pressure on the plunger it will block the return port in the master.

If there's just a little trash in the return port, pushing the caliper piston in will create a good amount of pressure. It should un lodge it without having to take apart the master. If this is the case, you would probably see some trash in the reservoir after you push the caliper piston in. |

|

#20

|

||||

|

||||

|

I know what you're talking about tk.

syringe won't push fluid through. backblast to the face when the line pops off the bleeder, watch out LOL ... Are your banjo bolt washers the style with the rubber center seal? if so, there's likely some bits of that rubber plugging up the master port/s. on the other side since it likely went up the lines to the master. Those things are the worst, little bits of rubber chunk off and get in the fluid real easily when changing lines, calipers etc. Had it happen to me several times. Had to leave the rig on the trailer at a race once because of that crap. go to the local auto parts store with a banjo bolt and buy copper crush washers in the right size. replace all the washer with those and you're gonna have to open up the master to get the crap out. you'll need snap ring pliers to remove the plunger rod and seal, then it's just a spring and the piston. blow out the lines and calipers with compressed air and start over ...fun, ain't it? |

|

#21

|

|||

|

|||

|

There's a good argument for not pushing fluid backwards to the master.

|

|

#22

|

||||

|

||||

|

I can answer that argument. You never never ever back bleed brakes. The piston seal in the master is a cup type. When back bleeding more times than not the fluid will force lips of seal to pop out in the opposite direction ruining the seal. When installing the master it must be bench bled first before the lines are connected. When everything is connected and master is full open the nearest bleeder, open valve then push pedal down, holding pedal down close off bleeder. Repeat this step until a good stream of fluid comes out than go on to next nearest brake and repeat until all 3 brakes have a good stream of fluid. You have to make sure that master does not go dry or you will have to start all over. Now that you have a good stream of fluid using the 1 pump method you will repeat again but this time pumping the pedal 5 times and holding then bleed off that brake until no sigh of air comes from that line. Repeat this as well for all brakes starting nearest to master to furthest. If done in this manner you will use less fluid and time. Possible that you can have a bad master cyl.

|

|

#23

|

|||

|

|||

|

Other than a power bleeder, I've found no faster way to bleed brakes then to use the clear hose on the bleeder method.. Like a power bleeder, it keeps the air and the fluid moving so the air doesn't have a chance to float back up hill. And it keeps the dirty fluid going in the proper direction, out the bleeder.

|

|

#24

|

|||

|

|||

|

well after beating my head Friday and Sat. I was about to give up. But decided still had one thing to do. Blow out the entire system with air. Got up first thing Sun. Took the Master apart. disconnected the brake line. and took out the bleeder. Spent about 20 mins making sure everything was clean as I could get it. Now since I already had the master cyl apart, went a head and bleed the system as suggested on BD website. Turning the master up side down, connected the master to the brake, removed the piston. filled from the res. let fluid come out of the master. Then put the piston back. then kept filling with the bleeder open this time. Bleed it out until about 5 Res. went through without any bubbles. shut the bleeder. Then put the rod and clip back in on the bottom, while still upside down. (which is a pain when it full with fluid and the damn shock is in the way. ) But got it done. Pumped the brakes and finally had pressure.

For some reason dont have as good brakes as did earlier this year. Brakes will lock up on dirt. But not on pavement with me in it. However, brakes are good enough so that can be driven safely. I have plenty of pad, so not sure what the deal is. However, thanks everyone for the help. If I never bleed another brake in my life, will be to F-ing soon. |

|

#25

|

|||

|

|||

|

Did you maybe get fluid on the pads?

|

|

#26

|

|||

|

|||

|

I got fluid everywhere.

. Its possible that could be the case. If have time today, going to car wash and give it a good cleaning. . Its possible that could be the case. If have time today, going to car wash and give it a good cleaning.

|

|

#27

|

|||

|

|||

|

Washing brake fluid off pads is as simple as rinsing them off with water, as long as you do it before you get the pads hot.

Once the pads get hot they kind of soak up the fluid. Clean them off and just ride it, they'll get better as the pads wear. Last edited by liduno; 04-13-2015 at 09:16 AM. |

|

#28

|

|||

|

|||

|

Thx for info lid. Well noted.

Side note: when filling the system this last time, when filling from the RES. I noticed the bubbles coming up. But at one point the fluid wasn't going down. And still didn't have the master filled yet. So grabbed the line connecting the two. Twisted it. Turned it. And tapped it. Finally got more bubbles to come up and the fluid filled the master. When filling the line to the brake I did the same thing. Don't know if that was a big factor. But at one point there was air trapped in the line, and wasn't coming out with some help. |

|

#29

|

|||

|

|||

|

Air bubbles can be sticky little boogers..lol Tap on the line with a wrench to make sure they're all out.

|

|

#30

|

|||

|

|||

|

I have a 150 that has been in storage for years. The brakes actually worked fine, but after hauling it home, cleaning it up, washing it off & so on, the Brake switch will not activate, no brake light, no starting. I took the switch all the way out, and there is no fluid, long story short I bought a new MC, and bled out the brakes- all is well. Except the brake switch still does not activate. I push the brake pedal down, loosen the brake switch until some fluid comes out, tighten it up, repeat. and repeat and repeat. Getting fluid out the threads of the brake switch, but it does not activate. Any ideas what I am missing or just keep doing what I am doing?

|

|

#31

|

||||

|

||||

|

There are 3 things to look at 1) make sure the master is bled before installing. Many will put the new master on, fill and bleed brakes. You might have some air trapped in the master. 2) check the switch with a volt/ohm meter to make sure it is working. 3) If no air in brake system and switch works check the wiring to the switch. Depending on the make of buggy some use a control ground setup in other words 12v power is run to accessories and the switch completes the ground some will use a completed ground to accessories and the switch will complete the 12v.

|

|

#32

|

||||

|

||||

|

The Yerf uses the brake switch as a starter safety and is not part of the master cylinder. What buggy are you working on?

|

|

#33

|

|||

|

|||

|

I have a 150 2R Carter Brothers Talon. After bleeding the brakes- I did not bleed before install as you suggested, but thought all was bled. I noticed the brake switch/ignition link is on the right side piston, which also supplies the rear disc brake. As I loosened the threaded brake switch, pushed down the pedal, tightened the switch back, released pedal 50 times or so... I noticed tiny bubbles venting from the bottom of the right side of the MC. It struck me that even though I thought I had the brakes bled, there was air trapped around the brake switch that was not working and not totally bled. I just re-bled from the rear disc with my vacuum bleeder, and boom, all is well. Works perfectly. The clue was the bubbles in the MC when I pressed and released the brake pedal. Thanks much for the help.

|

|

#34

|

||||

|

||||

|

Most people think that when you change out a master all one has to do is bleed the front and rear brakes and it will push out all the air. If you were to look at a master cutaway you would notice that the ports which feed the fluid are not strait forward of the piston but to the side of the piston. This leaves a void for air to collect at the extreme forward area of the cylinder. You can bleed the brakes all day long and never get to that air pocket. This is the reason you have to bleed the master cylinder first. The switches used regardless if used for a safety start or brake light operate with pressure of the fluid. As you press down the pedal the fluid pressure closes the switch allowing current to flow from the switch for either starting or brake light operation. If you have an air bubble at the switch, there is not enough pressure to close the switch since the air is never going to compress as much as the fluid, this is referred as air lock. Further, after bleeding the master cylinder you will always start bleeding from the furthest from master to nearest ie. rear than right front. left front.

|

|

|