|

|

|

#1

|

||||

|

||||

|

weird name, even weirder creation. Egged on by guys like Short Circuit, I finally got started.

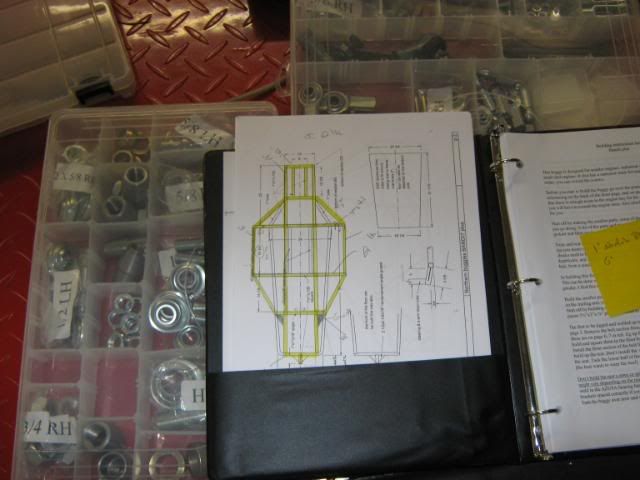

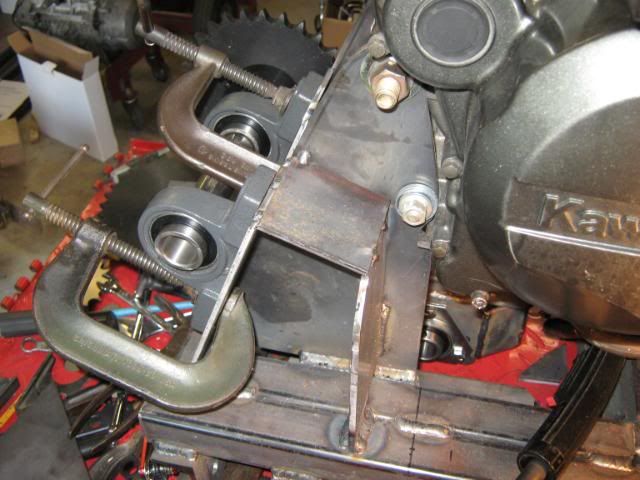

Bought some Bandit plans off ebay from Theo, VERY impressive! Then saw some sidewinder pics....I LOVE working with square tubing. Found out the cabin area of a standard bandit might be a bit cramped for me... So the "Puddle Jumper" is about to be hatched...... hear's the beginnings.   I could NOT work without clamps...   That's it for today....you can probably see more SideWinder influence right now, but the Bandit will be their too. Power plant was originally slated to be a KZ440, but I have sinse changed my mind, and think I'll put a KLR650 in this instead...

|

|

#2

|

||||

|

||||

|

ooo laaa laa...looks pretty cool to me.

|

|

#3

|

||||

|

||||

|

off to a good start

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#4

|

|||

|

|||

|

Bout time. Good start man. Why the big square steel?

|

|

#5

|

|||

|

|||

|

I see Bandit plans on the table.

Good Start and looking forward to the build Mark |

|

#6

|

||||

|

||||

|

It was in the steel rack, already bought and paid for....

And it follows the design parameters of the sidewinder. And it follows the design parameters of the sidewinder.

|

|

#7

|

||||

|

||||

|

Had to bring out the big gun today. My little 110V Lincoln was fine for the 1/8th > 1/8th joints, even though it was maxed out. So as some metal gages were increasing, I decided to move the gas cylinder over, and dust the cobb webs off my 220V machine..... NIGHT and DAY....

So with the frame turned over on the table, and all the welds finished on this side, I went the down and dirty, quicky way of rear suspension supports....yup, 3/16th gage 3" channel steel. Cut it all out, drilled it, lined it up, and the 220 machine sewed it up like nobodies bidness.   Gotta head for the u-pull-it yard this week, and pick up a bucket seat, so I can start on the cage next..... |

|

#8

|

||||

|

||||

|

Nice job

|

|

#9

|

||||

|

||||

|

More done today....bracing, gussets, spindles fitted to king pins, king pin bushings pressed in(still gotta bore, ream, & fit),,,

Once I finish with the king pin fit, then I'll weld the spindle & king pin solid. I just don't like bolts butt welded to king pins....fitted joints, mean strong joints..... |

|

#10

|

||||

|

||||

|

lookin good! What are you going to do for a powerplant?

|

|

#11

|

||||

|

||||

|

Kawasaki KLR650. Picked up the bike for a song about a year ago, parted most of it out, still got a few odds & ends, but as is, currently, only have 350.00 in the engine after all the parts sales. It's an '01, that only had 3200 miles on it, and ran like a swiss watch.

But if it isn't strong enough, I'll bore it to 685cc, drop the compression, and put a small turbo on top.... |

|

#12

|

||||

|

||||

|

I'd say it will be fine. The raptor engine on my sidewinder buggy was an excellent combination.

|

|

#13

|

|||

|

|||

|

Are finding your kingpin off the rims your using? Also are you figuring in corect akerman? I know alot of folks dont worry about it on buggies but then you end up with a cow like my Joyner.Also, do you bevel the ends before you weld or even leave a slight cap? I know some do and some dont

|

|

#14

|

||||

|

||||

|

Quote:

QUOTE "Are finding your kingpin off the rims your using?" 30+ years of various frame fabbing, suspensions, engines, etc.... I think the ackerman angles I build in will be satisfactory. Besides, Theo's plans are pretty "right-on" anyway. I bevel all my welds. I leave ends, "as machined" simply to inspect fitment, before bevelling, |

|

#15

|

|||

|

|||

|

Kingpin should be center of the rim. Depending on rim size and off set would depend on proper kingpin. Most builders dont bother but then most of the top builders say you build a car from the rim in.

I find it easier to bevel verse gap myself. |

|

#16

|

||||

|

||||

|

In a perfect world, of cars designed a century back, yeah the kingpin should be rim center, but then for proper loading, rim center should also divide the plain of both wheel bearings, about 50 years after the kingpin rule...

But as we all see today on various builds, the king pin, for performance orientation id usually inboard of the rim completely. The amount of inset can also be used to exaggerate ackerman, and on many straight axle, oval track cars was for years. The inside spindle would be longer than the outside with the rim spaced further away than the out board rim. Lots of trial and error, from the 40-70's. It's not going to be anything special, but we'll get together somewhere this fall, and you'll be more than welcome to try 'er out for an hour or 2.....long as you put a set of wheels under me too....LMAO!  Yeah, I've known some guys that "gap" too. Just seems counter productive to going for a good fit in the first place.... Last edited by kliff; 04-30-2010 at 05:30 PM. |

|

#17

|

|||

|

|||

|

Most buggies dont have ackerman or kingpin and most builders dont know what they are so I'm sure you'll be fine. I just like to pick brains on certain things. I got a 150 you would love as well as a piece of junk hh250 and the old joyner so seat time is no problem

|

|

#18

|

||||

|

||||

|

nice stard man now i wanna build another buggy haha Cool!!

__________________

MY HELIX -20' maxxis tires -1 1/2in.UNI air filter -gutted exaust -extended lugs -headlights -reflectors -my stickers -adjusted suspension -ground out hubs (to fit on the tires) helix 150 |

|

#19

|

||||

|

||||

|

more...

__________________

kliff |

|

#20

|

||||

|

||||

|

Couldn't come up with the cash for any cnc mounts this week, fuel pump in the truck died...

So I broke out my old Plasma cutter...  Even tried my own flavor of CNC, to get two identical copies....LOL  Worked, just like always, just a little slower, a little more labor intensive...but it worked...   And a little "mock-up" for the next stage:

__________________

kliff |

|

#21

|

||||

|

||||

|

Before y'all jump on me, lemme preface the cage fabrication with a little bit of history...

I ain't as nimble as I once was(arthritis, etc) and entry/egress could be a problem here. So if my design looks a little lacking, now you know why, besides look at some of the "over the counter" rigs... Mine is at least .120" thick everywhere you look.... evn it "balls" are 120 thick. Yeah, the balls will probably be another point of discussion. Frankly, I've never built with then, since the good old days of Tinker Toys, but I saw the idea on another site, and thought I'd give it a shot. If when I'm finished, it doesn't look stable enough, or for any reason even gives me a hint of weakness, I'll cut it off and bend up a DOM cage. This is just an experiment, and not recommmended for anyone to copy. PS..it ain't finished either...LOL  Working on the front control arms too...   And in his spare time, Dad decided to close in the back porch on the shop, and establish a separate "Buggy Parts Room." With it dried in, and shelves on one wall doe, I started moving in...   As you may have already surmised, with the variation, and quantity of parts going in, the Puddle Jumper will NOT be the last project....only the first.....

__________________

kliff |

|

#22

|

||||

|

||||

|

i think the balls will work as good or better than with a bender.ive made every thing on mine without a bender and it makes it a little harder.the balls will make the job go a lot faster.

looks good

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#23

|

||||

|

||||

|

And they're CHEAP too. Lesss than $2.00 per ball, and weld beautifully!

__________________

kliff |

|

#24

|

||||

|

||||

|

no replys whats up with that?i guess most are thinking what balls?!

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#25

|

||||

|

||||

|

LOL.... I gues we're too far over their heads' for them to be seen....LOL!

__________________

kliff |

|

#26

|

||||

|

||||

|

Got some more done this week. Painted the rims, re-mounted the fronts with tubes, but went tubeless on the rear...

Started fabbing te radiator/fan mount,  And began back on the primary jackshaft bearing mounts.....

__________________

kliff |

|

#27

|

|||

|

|||

|

where did you buy the steel balls. Ive never seen that done that way before now. I like it a lot and you are doing really nice work

|

|

#28

|

||||

|

||||

|

__________________

kliff |

|

#29

|

||||

|

||||

|

Let's revive this thread fellas, I'd like to see more on this thing, how's it been going Kliff?

__________________

2006 -ish Tomberlin Punisher Uni filter, no rev CDI, high output coil, iridum plug, 130 jet, semi gutted exhaust -Drive it like it's on fire! |

|

#30

|

||||

|

||||

|

i think kliff is having a bad time now.i seen this on another site

http://buggynews.com/kliff-needs-our...rs-t26568.html

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

|