|

|

|

|||||||

| FrankenBuggy Tech Unconventional and Home Built Buggy Tech Forum |

|

|

|

Thread Tools |

|

#1

|

|||

|

|||

|

I am in the parts gathering stage of this scratch build of a buggy. I already have a 17hp B&S opposed twin, 5-speed manual mower transaxle, centrifugal clutch, and a 1" gocart solid axle. I mentioned the plan in the welcome section but it probably belongs here. I've built roll cages, bumpers, and even redesigned suspension on lifted trucks, so a chassis shouldn't be out of my ability. The front suspension will probably be off an old ATV, I have a few options(friends ATV parts) so not sure on the exact model. Plumbing pipe chassis, 2-seat, and rear suspension will be dual swingarm. Shooting for 25" tires and hopefully bump the motor up a few ponies.

I posted this in the welcome thread but will put it here also for reference. I got the idea from a guy who started building, or at least posted in 2005. Here's a link to all his pics and a couple to give you an idea of what I'm looking to do. http://www.sadik.net/gokart/pictures/    I plan to use 2 3/4" heim joints at the frame end of each swingarm and space the pillow blocks out farther, into the wheel as far as possible. I'm also planning on running tha mower transaxle at a slower speed, then gearing after it to increase the speed. Mower transaxles don't like going too fast and only have bushings inside. Though mower racers do push them and I've seen and ran modded mowers go into the 20's and 30's. Still, the slower it spins the longer it should live. I know it's hard to comment on something that isn't built yet, but if you see any problems with my plans please let me know. Thanks for looking. |

|

#2

|

||||

|

||||

|

Very nice. You and MetalStudMan will get along real well. Nice job and great pics. Welcome aboard.

|

|

#3

|

|||

|

|||

|

Not my pics, just a representation of what I would like to do. Thanks for the welcome.

|

|

#4

|

|||

|

|||

|

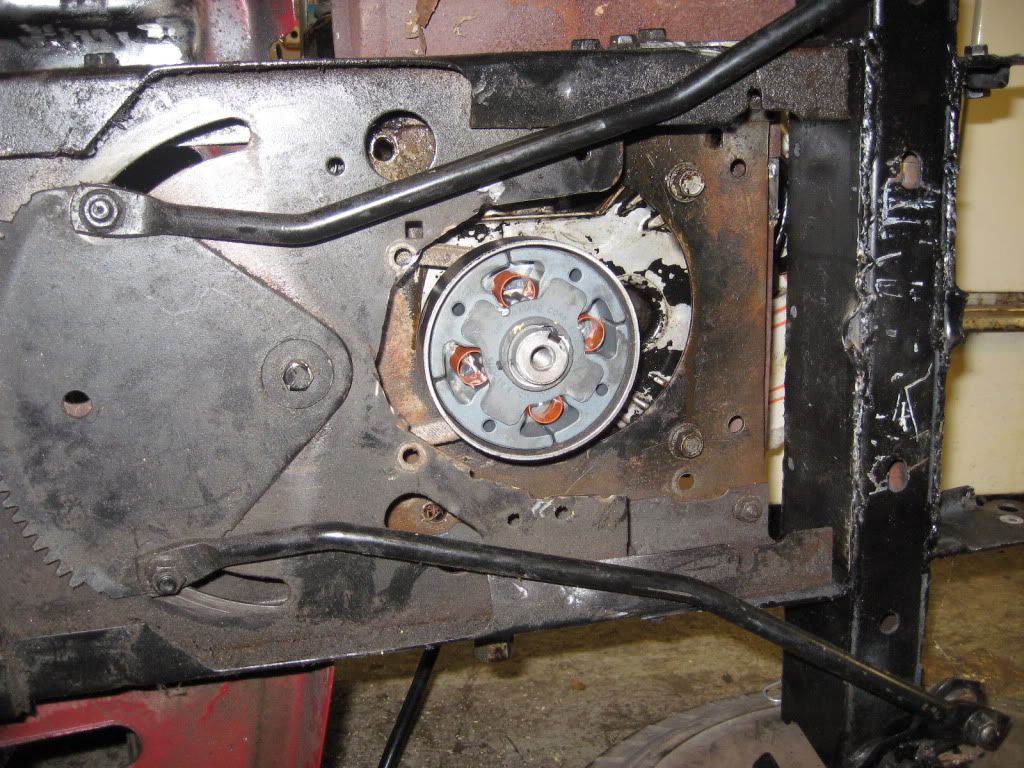

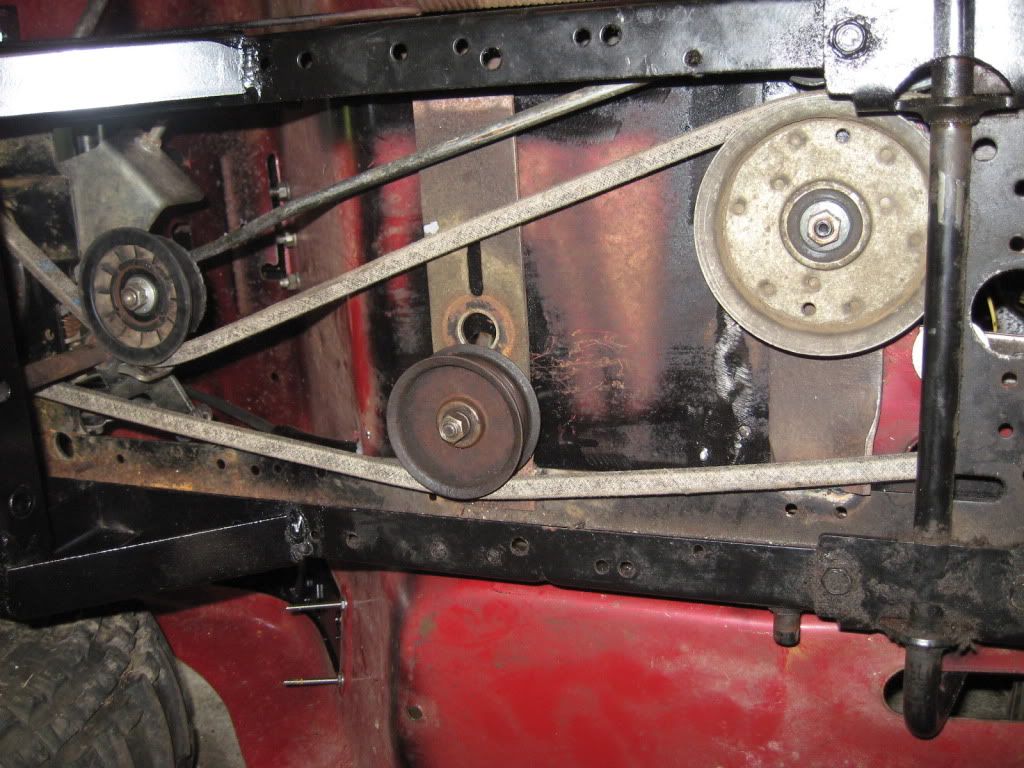

Yesterday I installed the centrifugal clutch in my offroad mower, which is the donor for the parts for this buggy. I disconnected the stock manual clutch and left the tensioner to use a new belt I had on the shelf. I'd have test ran it but the starter needs a rebuild. This is just a proof of concept test to see how a centrifugal clutch works with the mower transaxle. It will be mostly the same setup in the buggy though, just chain drive off the transaxle to the independent suspension rather than tires bolted directly on.

|

|

#5

|

|||

|

|||

|

Not much of an update but I am getting a free ATV frame to work with for front suspension. It's a 93 Yamaha Timberwolf 2wd. It's complete except for hubs and brakes, but has the shocks, spindles, steering, control arms, and the rest of the frame back to the swingarm mount. Not sure how much hubs will be, but you can't argue with free.

|

|

#6

|

|||

|

|||

|

fleabay my friend, shouldn't be too much if I had to guess. Good luck, love the ideas here.

|

|

#7

|

|||

|

|||

|

Thanks, ebay was the only place I found anything. I still haven't received the frame though.

|

|

#8

|

||||

|

||||

|

ive welded truck wheels to the rims of a lawn mower with m/t tires.fun in the mud wile it lasted,broke the trans.

how big do you want the buggy to be?

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#9

|

|||

|

|||

|

Well, the only real goal is 2 seats and able to run the mild trails. I am supposed to be getting a peerless 700 from an old Gravely walk behind mower. It's what a lot of the mower racers use, 1" shafts. I haven't done anything towards this project, summers are always busy. Any free time you get seems to be directed at odd jobs around the house.

|

|

#10

|

|||

|

|||

|

Well, here's some pics of that atv frame. I still need to figure something out for hubs. Once I get the width figured out with hubs and wheels/tires, I'll decide how much it needs widened. I think splitting the frame down the middle and adding tubing will work fine. I thought about extending the suspension for more travel, but the strut design seems like it would be more trouble than it's worth. This will just be a mild trail runner anyway, something to take kids and elderly for rides, haha.

Last edited by Jamus; 07-12-2011 at 02:45 PM. |

|

#11

|

||||

|

||||

|

are you only going to use the front of the quad?the extra travel will help more than you think.

imo build aarms so you can have what you want.its not that hard,ive done it for the first time and its not as hard as everyone makes it to be.good luck on your build if you need help just ask

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#12

|

||||

|

||||

|

Wow Guty that thing will be radical as H^^^L. Sure looks like you do some darn fine fabrication work. I wish i still had my garage but all i got now is a 12x12 shed with no electric and a box full of tools. I would love to be able to create sumthing like that. You do nice work. It should be awesome keep the pics coming !!!!

|

|

#13

|

|||

|

|||

|

Those first pics aren't mine, just inspiration for what I had in mind. Though now, for the sake of getting it done sooner, I'm thinking of building a single swingarm.

|

|

#14

|

|||

|

|||

|

I have these 10" tires on bearings that I got for cheap. Do you guys think that the bearing unit could be used as hubs for the front of this buggy? They fit 5/8" bolts and I could make a plate to adapt to a 4x4 bolt pattern.

Last edited by Jamus; 07-21-2011 at 04:54 PM. |

|

#15

|

||||

|

||||

|

imo try it.the buggy wont be real fast so thay may work.

what wheels will you use?

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#16

|

||||

|

||||

|

Wheelbarrows are not high speed. Most likely you will need to replace those bearings with better quality ones and use an additional backing plate on that split rim if you want to use it as a hub.

|

|

#17

|

|||

|

|||

|

I guess I can try it and see. I plan to bolt a plate to this and bolt atv front rims to that. If these bearings burn out I can replace them with better of the same size right?

|

|

#18

|

|||

|

|||

|

"I got it one piece at a time..."

The next bit of puzzle found me today. I was in a Good Samaritan store today and found some atv tires under a sink. Asked the lady how much and she had no clue. She called the guy who does pricing and he says $10 a tire. So $40 and they came home with me. 25x8 fronts and 25x10 rears on 12" rims, which I now need to look for. The tread seems pretty good too. Good enough for me anyways.   Oh, and scratch the utility tire hubs, I found a place to get high speed bearing hubs for a reasonable price. |

|

#19

|

|||

|

|||

|

Got some parts in from BMI Karts today. Front and rear hubs, axle bearing kit, and some cheap disc rotors. No real update, but I like new parts. One problem I see though is with the rear width. With these hubs on, it's 32.5" wide at the mating points. I'm going to need some deep offset rims or spacers to get into the 50" wide range I'm wanting.

|

|

#20

|

||||

|

||||

|

One of my favorite lines ever on this site...spoken like a true man!

And I have to admit those are some awesome looking parts! Looks like it will be fun! |

|

#21

|

|||

|

|||

|

Started to put the new parts to use today. I welded some 5/8" grade 8 bolts to the spindles to accommodate the new front hubs I bought. That went pretty smooth, lots of heat in the welding. While I was out in the garage I also set the tires up at the width and wheelbase I think I'm shooting for, 50" wide and 70" wheelbase.

|

|

#22

|

||||

|

||||

|

looks likes a good start

__________________

http://www.youtube.com/watch?v=IUgir...ature=g-t=2668 FABRICATION ITS HARDER THAN YOU THINK |

|

#23

|

||||

|

||||

|

Great start!!Awesome welding!! Good use/fix of your 4-wheeler front suspension. I got some questions: are you going to put the spacer on the front axle behind the hub instead of at the nut? The 70" wheelbase is LONG for even a 50" width-right now you're at a 40"-44" width with basic wheel configuration (those big lug bolts puts you in the golf cart, racing or trailer wheel industry unless you drill out the holes). Is there a reason for the 70" length? Are you still using the lawnmower frame as it is or are you stretching/widening it?

|

|

#24

|

|||

|

|||

|

The 50x70 is just a rough size based on 2-seat UTVs with the same size tires. As you can tell, I'm bouncing back and forth between a golcart/utv and buggy design, or shape. The chassis with be all custom, no lawnmower. Really the only lawnmower parts will be the engine and transmission.

Oh yeah, that spacer is not what I'll be using, it's 3/4" on the 5/8" spindle. It was either get this bolt and need a spacer, or get the next size shorter bolt and have the outer bearing ride on some of the threads. I opted for the longer bolt. As for where the spacer will go, could go either way I guess. I'm hoping to put a disc brake on the back of that hub, so the spacer might add space if it's needed. Everything is still very loosely in the planning stages. And I adapt to whatever cheap/free parts come my way. Perfect example is the transmission, which I have not even seen yet, much less received. |

|

#25

|

||||

|

||||

|

Now I understand your logic!!!!

|

|

#26

|

|||

|

|||

|

Not sure if I'd freely use the word logic to describe anything I do, haha. I have probably made this thread confusing with the pictures of someone elses buggy and then my mower. But I've decided to run a simpler articulated swingarm with a single chain and solid axle, so those first pics are irrelevant.

I do have a question on strength though. Will #40 chain be strong enough for what I'm building? The reason I ask is that I was in tractor supply and saw one of their smaller UTVs with the 9hp subaru motor, and only 22" tires, and it had double chain/sprockets running to the axleshaft. Maybe just overdone for insurance purposes? The place I'll be getting chain and sprockets is about the same price for #50 as it would be for #40 I think. |

|

#27

|

||||

|

||||

|

How big is the motor? #420 (#40) is the smallest chain I'd use, but there are many karts out there with 6.5hp motors running #35 chain (mostly single wheel drive) The issues you'll have is matching the jackshaft sprocket with the axle sprocket size- very few off the shelf jackshaft sprockets with #40 or bigger chain size.

|

|

#28

|

|||

|

|||

|

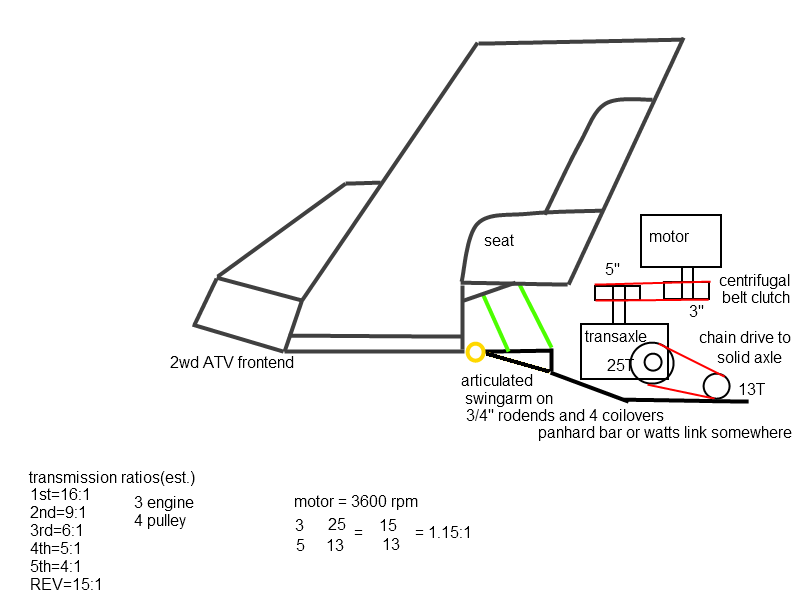

Well, here's how the drivetrain will be run. 17hp twin cylinder mower engine(3600rpm gov. but I may un-govern it someday) run to a 5-speed transmission, then chain drive off the transmission to the axle shaft. The shafts for chain are all 1" keyed so no problem on sprockets from 13T up to like 48T. The actual ones I plan on are 25T on the transmission and 13T on the axle. The reasoning is to speed back up, mower transmissions are meant to be slow. This way I'm not over-revving the transmission too. I'll try and draw up a pic with paint to show what I'm thinking.

|

|

#29

|

|||

|

|||

|

I found I had already done one. The only difference is that the transmission I'm going to use now has the pulley on the bottom rather than on top.

|

|

#30

|

|||

|

|||

|

Bad news. Got the gravely tonight and it isn't what I thought it was. It's build more like a tractor, with the motor/gearbox/axle being one unit. I don't see that being of any use to this project, so I'll probably try and restore it. This really puts a damper on the project.

|

|

|

|