|

|

|

|||||||

| 150cc GY6 and Under Engine Tech GY6 and Smaller Technical Discussion Forum |

|

|

Thread Tools |

|

#1

|

|||

|

|||

|

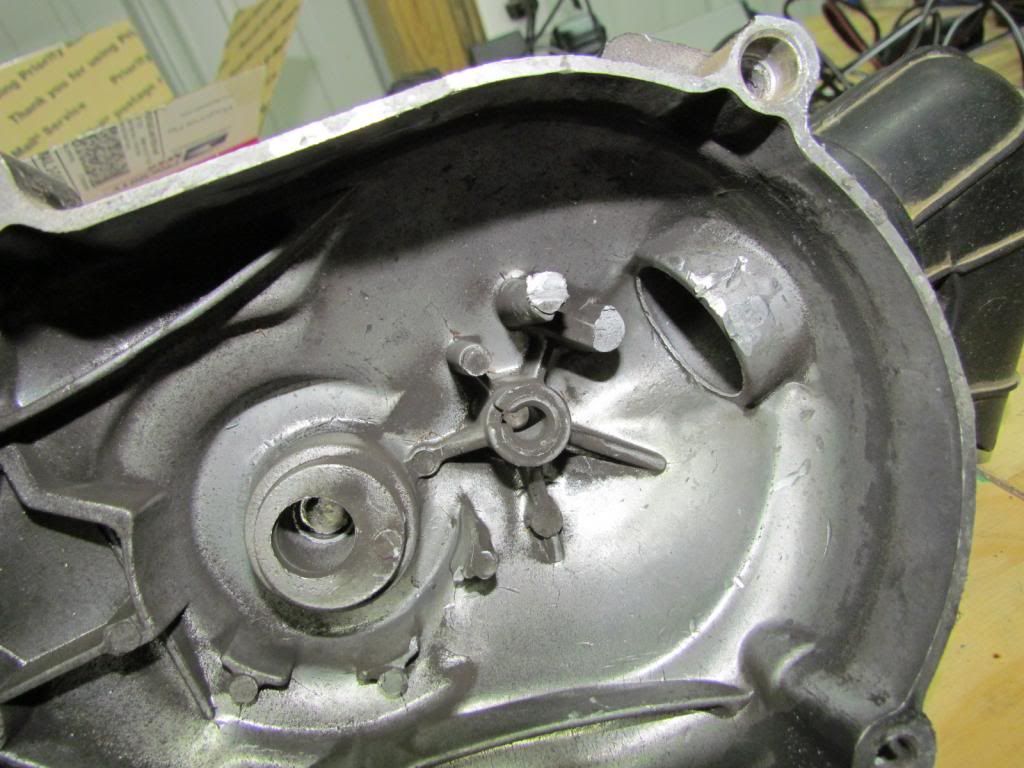

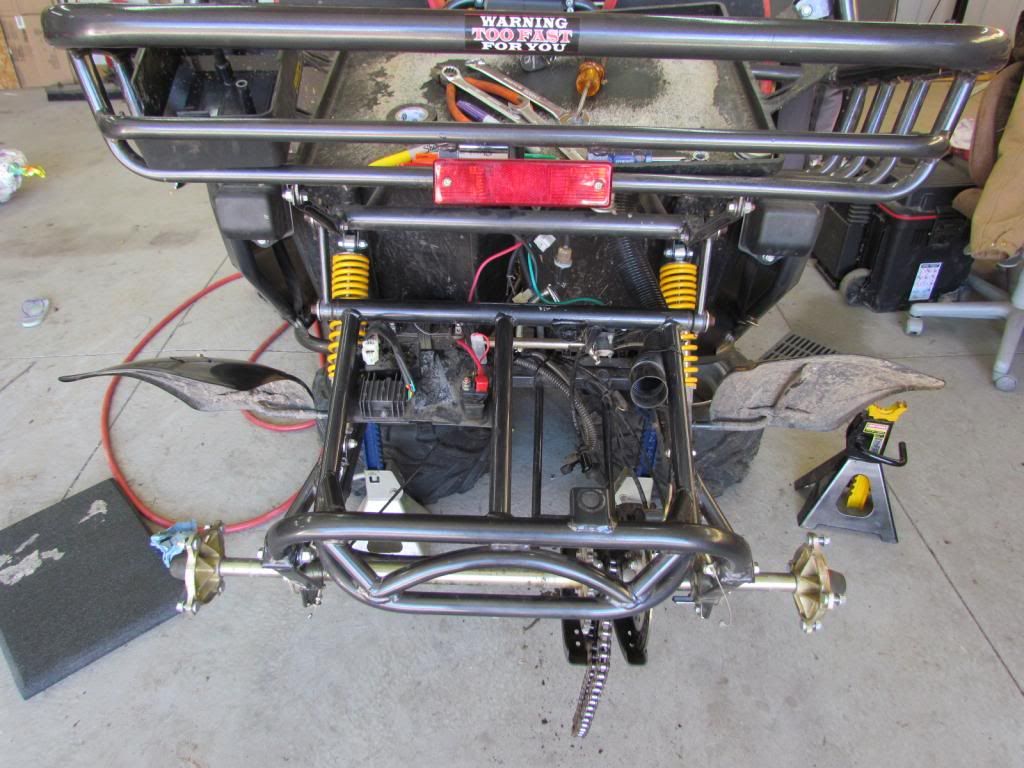

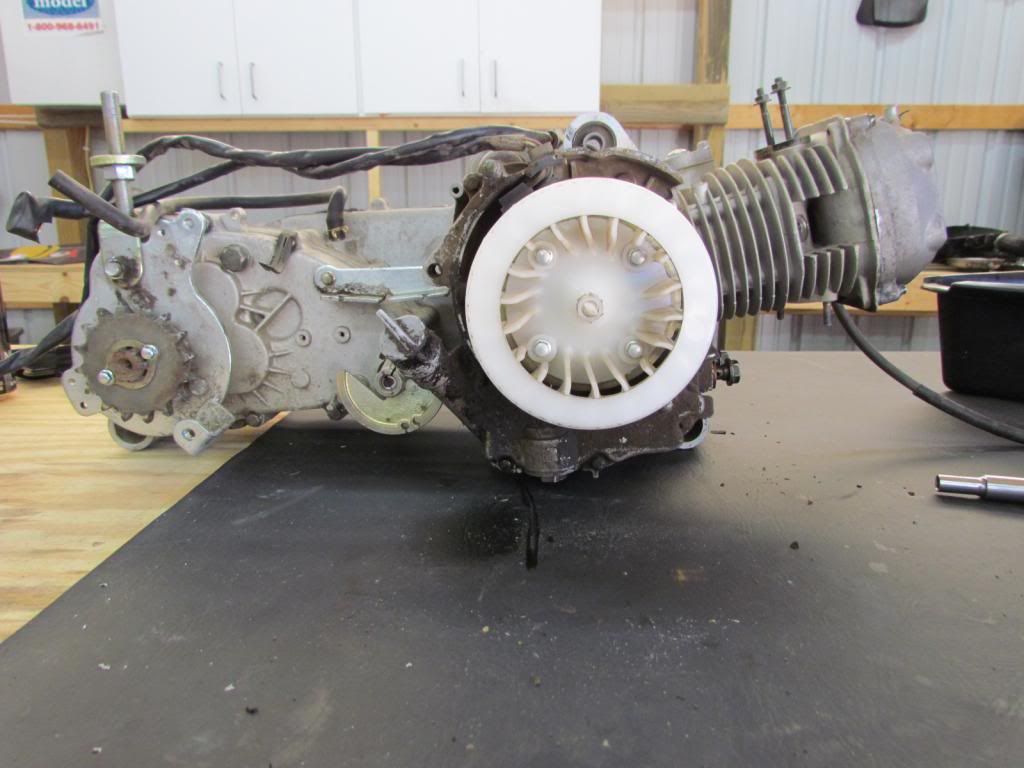

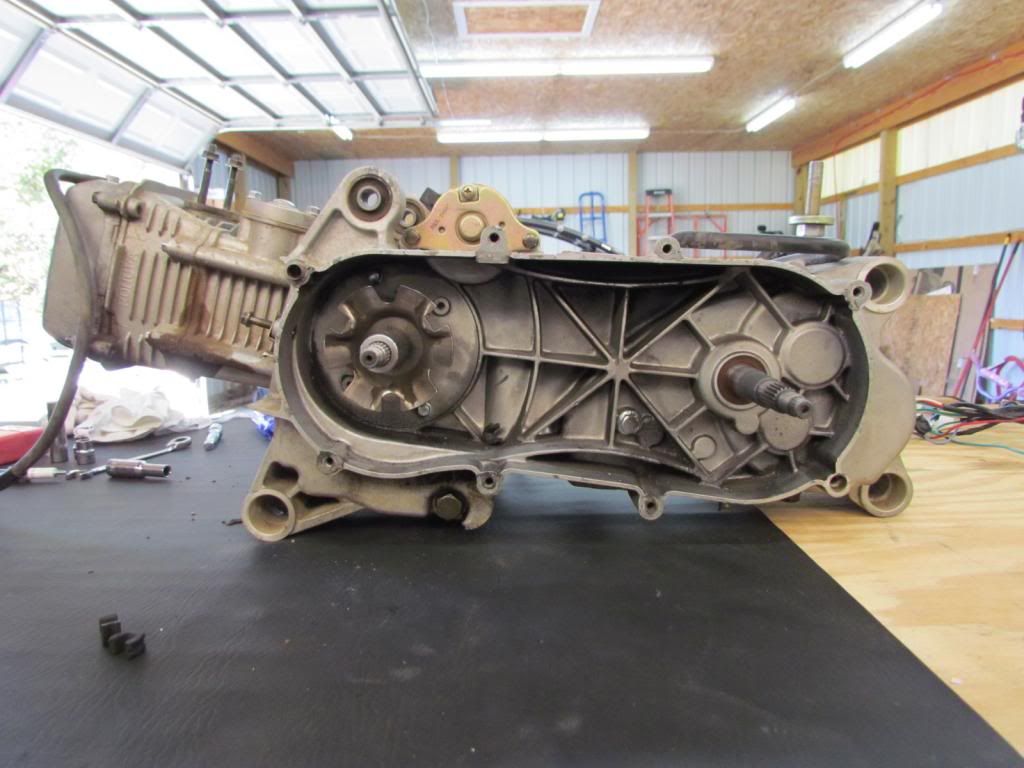

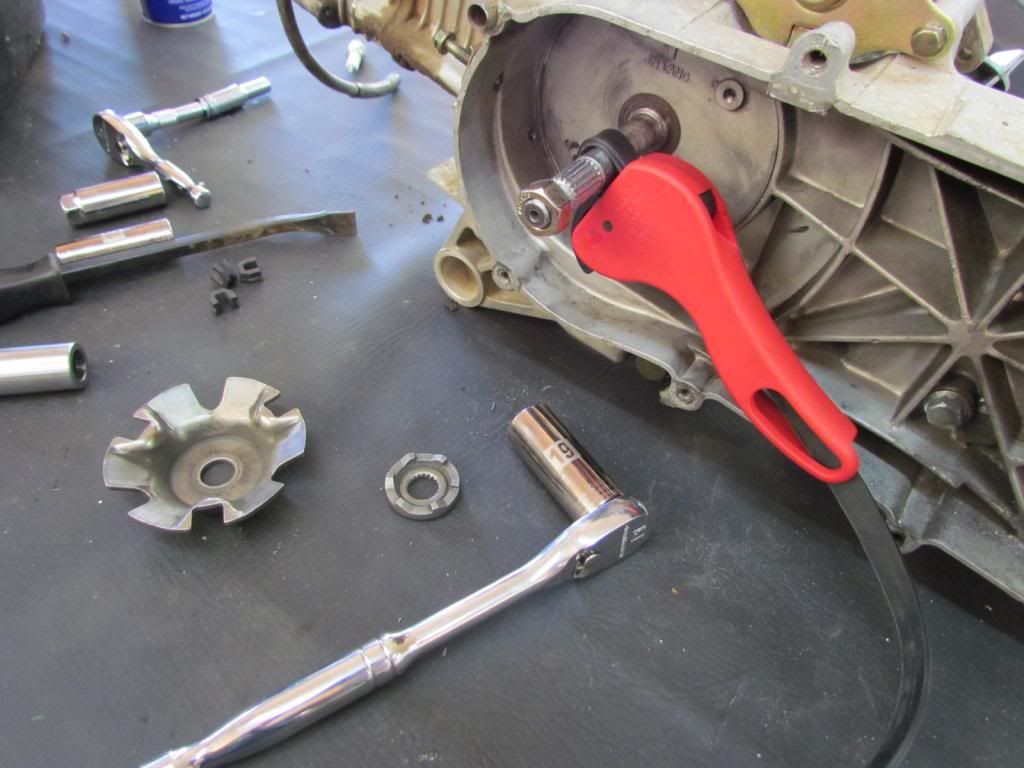

2009 ASW Carbide.

I installed 1500rpm main spring, 10gram sliders, UNI filter, redneck intake, adjustable CDI and re-jetted. After letting it idle all seemed totaly fine. Went for a test drive and after about 10 minutes i hear TINK TINK TINK TINK TINK. I shut it down immediately and pulled it back to the shop with my other ASW Carbide 7150. This is what i found when i took it all apart. Variator splines completely gone, and fins broken off.  The Variator hit the cover, explains the fins broken off   Destroyed the splines and threads. The splines are so mangled i cannot get that roller thing off or the back of the variater.  You see the bolt head at the bottom of the case under the variator back? Do you see the hole above it? That hole was a bolt that the variator back busted off somehow. There where 4 of these bolts, two of them got knocked out. What are they?  I have no idea what even happened here. So what am i looking at for repair of this? If i took the engine out and bought all the parts what do you think a shop would charge me? Better to do it myself? Anything i need to know about removing the engine? How heavy is the engine? Can one guy remove it? |

|

#2

|

|||

|

|||

|

Not sure where to go from here.

Order seals and crank and then find a shop or do it myself.

|

|

#3

|

||||

|

||||

|

It looks like you already did all the hard work. Was the bolt still still on shaft holding variator when you opened it up?

__________________

Growing old is mandatory  Growing up is optional  https://www.youtube.com/watch?v=NEXoa-8d7qE |

|

#4

|

|||

|

|||

|

Im just not sure if i want to tackle this myself or not.

I have to figure out what i will need for parts. What seals do i need? Are the crank shafts on these different than others? Im assuming so. Both the carbides do not have the starter gear on the crank shaft like i see all the others have. |

|

#5

|

||||

|

||||

|

I was just asking because I was thinking maybe it could have started to spin loose and grind It down and destroy it like that.

I say go for it. If you want to spend money and know a good scooter mechanic then send it out.

__________________

Growing old is mandatory  Growing up is optional  https://www.youtube.com/watch?v=NEXoa-8d7qE |

|

#6

|

||||

|

||||

|

Do you have all the manuals?

Links for manuals?

__________________

Growing old is mandatory  Growing up is optional  https://www.youtube.com/watch?v=NEXoa-8d7qE |

|

#7

|

||||

|

||||

|

http://www.amsportworks.com/manuals_7XXX.php

Click on the 7150 and there is all your detailed info.

__________________

Growing old is mandatory  Growing up is optional  https://www.youtube.com/watch?v=NEXoa-8d7qE |

|

#8

|

||||

|

||||

|

What I don't get is what tore the crank splines up. It surely wasn't from the soft aluminum variator fan.

|

|

#9

|

|||

|

|||

|

That has me confused too, nothing else could have done it though.

Im being told i could clean up the splines with a file and chase the threads and i should be fine. I geuss its worth a try. Not sure how im going to get the boss pin and the backing plate off though. |

|

#10

|

||||

|

||||

|

Quote:

as far as getting the sleeve off the crank, I'd lightly file the crank right next to it followed by a bit of fine emery polishing. those sleeves can give fits even when everythign is normal. i'm among those who think you may be able to get away with cleaning up the splines and threads. |

|

#11

|

|||

|

|||

|

Check it out.

I went to harbor freight and bought the 4 piece puller set and 2 different packs of files. The puller i used worked amazing. The boss pin and the variator back came off like butter.  Puller set up   And victory  Of course gotta have a helper  Stay tuned |

|

#12

|

|||

|

|||

|

I then filed each spline on the crankshaft. It was tedious but worked.

I slid the thick splinned washer on to test it since its the only thing that survived unscathed. Another victory

|

|

#13

|

|||

|

|||

|

i then went to a lot of stores looking for a m12x1.25 die.

NO ONE HAD ONE Surprisingly autozone did but they only had it in their rented set, so i had to rent the set, no biggy i get all my money back. Worked great I tested it with the nut from the clutch since its the only m12x1.25 to survive the carnage.    All done

|

|

#14

|

||||

|

||||

__________________

Growing old is mandatory  Growing up is optional  https://www.youtube.com/watch?v=NEXoa-8d7qE |

|

#15

|

||||

|

||||

|

So did the variator nut come loose? Good job on saving the crank, your motor looks different than the ones we have in our Baja 150s. Same design just the inside of your case is different. Our buggies don't have the 4 bolts or a built in reverse. As for paying some one to do your motor work it looks like you have got it all under control. Last summer 2012 I replaced the crank and bored the case to make a 183cc motor and the only hard part was figuring out how to get slack in the timing chain due to the 3mm of more stroke and the cylinder spacer and extra base gasket. I ended up wet sanding the head on our granite counter top with 400 wet sand paper for about a hour and a half to get 15thousand of a inch off the head. As for the variator nut I like to use blue Loctite and my 3/8 impact gun on the second of 4 settings.

|

|

#16

|

|||

|

|||

|

Not out of the woods yet.

Now I need a new variator and also figure out why it failed. The shaft can't take these failures often nor can my time or pocket book. I put everything back together in the right order, used locktite blue 242 and torqued to spec. It makes no sense why the nut backed out. |

|

#17

|

|||

|

|||

|

Oh ya, when buying a new variator is there anything I need to know?

They all the same for these engines? Any recommendations? |

|

#18

|

||||

|

||||

|

Make sure the belt is not holding the variator crooked or sitting in the variator and holding the pulleys apart. I take the belt and open the rear driven pulley about half way so there is no belt tension on the variator so when I tighten the variator the belt is not interfering with the variator fan, pin and rear pulley. You may have tightened the nut with the belt holding the pulleys open just a small amount and causing the nut to come loose on start up. After I put the variator nut on with the belt half way in the rear pulley I crank the motor over a few times to let the belt tighten back up before putting the cover back on.

As for stock variators I have about 3 and have no use for them, were do you live? |

|

|