|

|

|

|||||||

| 150cc GY6 and Under Engine Tech GY6 and Smaller Technical Discussion Forum |

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

I got a GY6 short case that has these two gold lugs and a swivel bracket. what do they attach to?

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#2

|

||||

|

||||

|

This motor is set-up for a scooter.Those tabs would be for brake shoes! if you're going in a buggy just remove them,the top post should just slide out when the fork bracket is removed then your bolt for your chain adjustment/rear engine support goes there.

|

|

#3

|

||||

|

||||

|

Cool! Thanks.

Do you have any experience with these  Rear axle assemblies? Rear axle assemblies?

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#4

|

||||

|

||||

|

Yes trying to get parts for them. Those were used on some of the small bargan China atv's. It seems someone is always calling for parts cause they tear up.

TOM |

|

#5

|

||||

|

||||

|

I looked at these a couple of years ago as an alternative to adding reverse. If I remember right- less than 30" hub to hub that's very narrow if you're intent is using it for a buggy even if it's a single seater!-

|

|

#6

|

||||

|

||||

|

The ring and pinion is not supported by any bearings, just bushings in the case. Bushings wear out thus wearing the case then the ring and pinion are destroyed. Most of these I have looked at were less then 2 years old. You cannot even find the internal parts, you have to purchase the whole unit which the last I checked were between 300-400.00. The small atv's only cost 500.00. Don't know if all these units are alike, all I can say is I have looked at about a dozen of these with all having the same results.

TOM |

|

#7

|

||||

|

||||

|

The one I posted was selling for $159.

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#8

|

||||

|

||||

|

Is it going on a buggy?

|

|

#9

|

||||

|

||||

|

I was thinking about it but decided to go the regular route: axle, drive gear, disc brake.

Had another question. Can I mount the engine to the swingarm frame and fab a adjustable idler gear to set chain tension?

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#10

|

||||

|

||||

|

you may be on to something here! . Sometimes during a hard pull my chain will go slack and at times will skip a tooth. I can blip the gas while holding the brake and watch the chain go slack. This has been a problem for me since day one. At one time I thought it was axle flex so I added a third center bearing support. This cured the axle flex but not the skip. Only thing I can figure at this point is the motor twisting in the rubber mounting bushing. The motor is held in at 3 locations, two at the front with bushing and a third at the rear which doubles as the chain adjuster. The motor needs a fouth mounting point in the rear to control twist but this would cause loosing the ability for chain adjustments without a lot of adjustment to motor mounts Solid mounting the motor with more/ stronger mounts and an adjustable idler gear might do the trick!

|

|

#11

|

||||

|

||||

|

I had the same issue and scratched my head many times trying to figure out why when climbing a steep hill the chain would skip a tooth- I'd check the tension and it would be tight--- I think you just solved this issue!!! it's got to be the twist on the motor- the new Honda engine is rigid mounted and it doesn't skip a tooth anymore. If you were going to put a tensioner on - I'd think you'd need the type that floats & compresses the top & bottom of the chain together.

|

|

#12

|

||||

|

||||

|

I just realized we have the same issue with race cars throwing fan belts. One of the remedies we use is a belt guide that is really just a bolt the sits an inch from the longest span of the belt and keeps the belt from whipping under high rpm. The other can be seen under the hood of most modern cars today. A spring loaded belt tensioner. Not to big a job to replace the tensioner pulley with a sprocket. They even have wear indicators to let you know when the belt/chain has stretched.

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#13

|

||||

|

||||

|

I think coming up with a place to mount your tensioner will be the biggest issue!!

|

|

#14

|

||||

|

||||

|

The only time I have run in to chain skip problems is when the bottom jamb nut for the chain adjustment was not tight, or when the bushings wore out. I have since replaced the front eng. mount bushings with nylon bushings as well as the rear case bushing which I had to make myself. Also the adjuster bushing I replaced using an automotive polyurethane bushing custom fitting it since you want some flex in this bushing. I have had no problems with chain skip since. Most don't realise that the rubber eng. mount bushings do wear and get weak allowing for excessive flex in the engine, also most don't tighten the lower jamb nut when adjusting the chain.

TOM |

|

#15

|

||||

|

||||

|

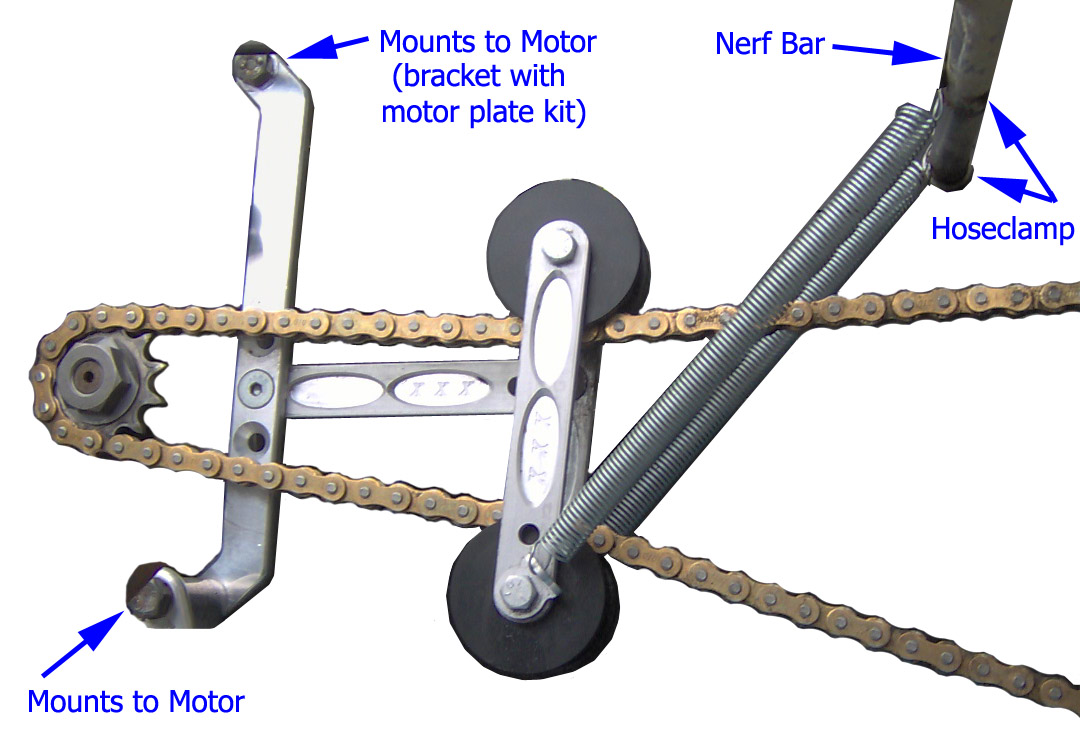

Doing some research I found this

Its a kit to self tension the chain. This is how it works

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#16

|

||||

|

||||

|

NICE set-up! The art work is great too!!!That's the same type of tensioner I was suggesting- I also saw one that is strickly nylon/nepreme (no wheels) that's used on textlie machinery at the bearing shop I shopped at till they closed last month.

|

|

#17

|

||||

|

||||

|

Reminds me of the set-up i have for my DH bike. Used to have a lot of problems tossing the chain over the really rough stuff til i bolted something very similar to the frame near the big ring.

|

|

#18

|

||||

|

||||

|

founnd this too. Looks easy and promising.

Applications Roll-Ring chain tensioners can be applied in a wide variety of fields of mechanical engineering. Roll-Rings have been reliably operating in printing machines, confectionary production lines, luggage conveyor drives/transportation systems at airports, cleaning and filling systems in breweries, roller conveyors in aluminium pressing plants, in chain drives on vibratory plates in automatic sand blasting machines, and in agricultural machines with heavy duty chain drives. *Roll-Rings have even been installed successfully on Quad bikes/buggies.

__________________

If the only tool you have is a hammer, Then all your problems look like nails. Last edited by Lyonsperf; 11-20-2011 at 09:11 AM. |

|

#19

|

||||

|

||||

|

Update! I decided to add a external alternator to the mix. It will be driven via the drive chain with a sprocket. chain adjustment will be made via the alts mounting brackets. This way I can run all the lights and extras I want.

__________________

If the only tool you have is a hammer, Then all your problems look like nails. |

|

#20

|

||||

|

||||

|

|

|

|